The 45-Second Trick For Plastic Bottle Suppliers

Table of Contents3 Simple Techniques For Plastic Bottle SuppliersSome Known Details About Plastic Bottle Suppliers Getting My Plastic Bottle Suppliers To WorkAbout Plastic Bottle SuppliersWhat Does Plastic Bottle Suppliers Mean?

The plastic in the mould strengthens as it cools. Once it has cooled down adequately, the 2 fifty percents of the mould open to ensure that the preform that was made can be secured. Address the following question about Number 2. 1. Discover the mould and also label it.Where will you place a heating unit on the device to thaw the plastic pellets? Draw an added part or parts for the device to show where the heating unit must be, and also tag it. 3. Look carefully at a plastic bottle. You will find a very thin ridge where the two parts of the mould joined.

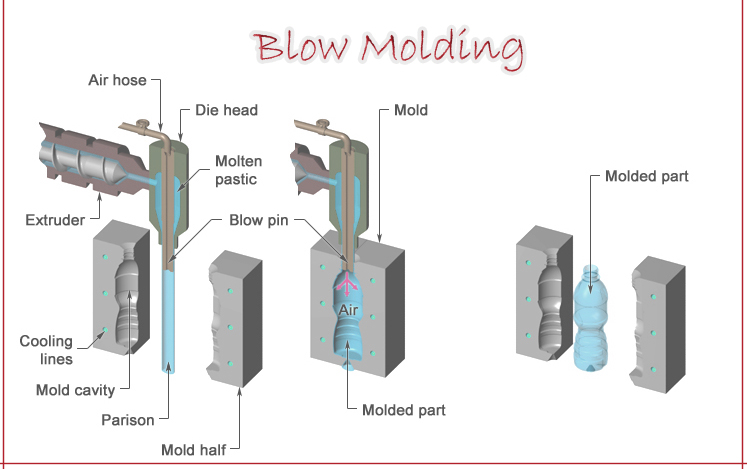

Why is the mould line on both sides of the neck? Figure 2: The injection-moulding process Following, the preform goes to a blow-moulding machine. This machine blows hot air under high stress right into the preform. This warms the reduced component of the preform to make sure that it comes to be soft and also can transform its form.

Facts About Plastic Bottle Suppliers Revealed

3: Blow-moulding of a preform to make a plastic bottle The very same kind of preform can be made into various shapes of bottles, given that it can be blown into different moulds (plastic bottle suppliers). However all the containers will have the exact same screw-on cap. 1. Why will all the different-shaped containers fit the very same cap? In Chapter 9, you found out why we ought to recycle plastic containers and also various other items.

Are all the plastic containers in the bin clean? Is this crucial? 5. Plastic containers and also other containers take up a great deal of room. Why is this a problem? 6. Name four things that require to be done to plastic waste prior to it will certainly appropriate to develop into new items.

Not known Facts About Plastic Bottle Suppliers

Each kind of plastic waste is pressed right into bales that can easily be transferred. At the recycling manufacturing facility, the plastic waste is shredded into tiny items, to make it less complicated to take care of and also clean. 7. Total the systems diagram below by providing summaries of the different steps of the reusing process.

Figure 4: Equipment layout of the plastic bottle recycling procedure Number 5: The steps to transform waste plastic right into new plastic products 1. What is the raw product for the bottles in this process? 2. plastic bottle plastic bottle suppliers suppliers. Just how can consumers and also house-owners make it less complicated for recyclers to refine plastic products to make brand-new bottles? 3.

How can this be done? 4. Which sort of moulding do you believe is used to make plastic chairs? 5. What is the distinction between shot moulding and also strike moulding? Over the next 3 weeks, you will do your Mini-PAT for this term. You will certainly recycle old plastic bottles for a brand-new function.

The Ultimate Guide To Plastic Bottle Suppliers

Carpet firms utilize recycled fiber to make polyester carpets. PET DOG is spun right into fiber filling for cushions and patchworks. Fiber is also utilized to make clothes, jackets as well as also polar fleeces. ANIMAL containers might also come back in the kind of non-woven automobile carpetings. Retailers utilize rPET in cushions, duvets and also reusable buying bags; automotive makers make use of rPET in boot linings as well as carpetings; architects as well as developers use rPET in the kind of roof insulation; garments designers make use of rPET in the manufacture of garments like jeans, fleece jackets, as well as innovative sportswear; designers use rPET in commercial applications, such as strapping, geotextiles for buildings, dams, power plant and also tunnels; brand name proprietors use rPET as a blend in brand-new bottles.

The Main Principles Of Plastic Bottle Suppliers

It appears like designers are becoming aware the potential of just how to make a business out of this sustainable material. Woolworths RE jeans: Woolworths launches their'RE' denim variety of apparel, taking on a cutting-edge manufacturing process making use of 12 x 500ml recycled directory plastic containers to manufacture each pair of recycled blues jeans. This represents the first apparel array made from rPET introduced in South Africa by a major store.

Astrapak cranberry juice bottle: Astrapak's 100% food grade rPET Cranberry Apple container is become part of the SAPRO (South African Plastics Recycling Organisation) Finest Recycled Plastic Product of the Year Competitors, representing a shift in the point of view of makers towards considering recycled plastics as a material of selection. 'My Office' an all-in-one felt material sleeve that houses your laptop, mobile and a number of other vital individual and also tech gizmos.

In concept, all plastics can be reused. Nevertheless, in method, it does not constantly make ecological, affordable or technological sense to do so (plastic bottle suppliers). For specific factors recycling plastics is not sensible; these are reasons like: The visibility, in one item, of numerous kinds of plastics which can not be separated as well as makes recyclability hard and expensive; The visibility of leftover food or various other products, which makes cleaning eco and economically tough; Long-distance transport, of little amounts of plastics, makes recycling non-economical as well as non-beneficial, as a result of low effectiveness and high costs.